Heat Flux Sensor: The Standard for Thermal Analysis

EKO’s Heat Flux Sensors accurately measure thermal energy flow for critical applications like Building Physics (ISO 9869 compliance) and R&D . The core HF-01S sensor is small highly sensitive, and features low thermal resistance to minimize interference, ensuring reliable data for evaluating insulation performance and heat transfer rates.

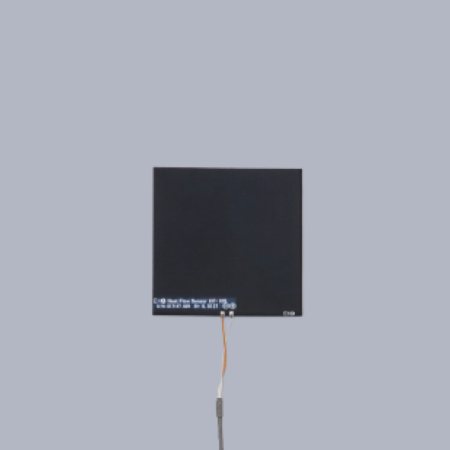

Standard Heat Flux Sensor

Small size standard plate type heat flux sensor | ASTM C1046 | ISO 9869 | Built-in thermal guard

Thinnest plate sensor

The HF-10S, at only 0.5mm thick, is a super-thin option for applications where the sensor’s thermal resistance must be minimal, ideal for a variety of research applications and manufacturing control processes.

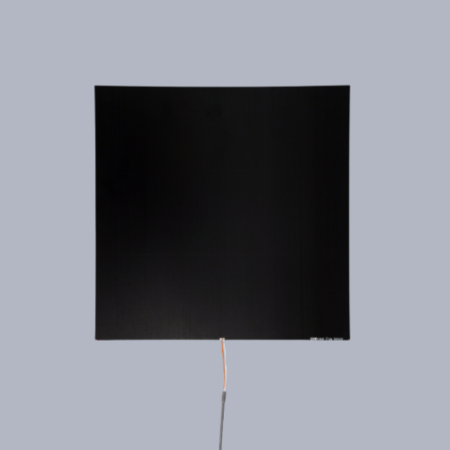

Extra Large 30 x 30 cm²

Weather-proofed, ultra-thin, and extra big. The HF-30S is perfect for measuring average heat flux over a large, flat area or surface.

Heat Flux Sensor Extension Package

Extend heat flux sensor cable with EKO Extension package to measure heat flux with high accuracy and precision on 20 meters away. Low resistance and high quality cables.