How Heat Flux Sensors are Transforming Building Energy Efficiency

Enhancing Heat Management in the Built Environment

Within the built environment, energy management has become a paramount global concern. The rapid depletion of fossil fuels necessitates an enhanced focus on energy consumption levels. As a result, the ongoing development and implementation of energy efficiency measures have taken center stage.

Among the critical challenges in energy conservation lies the issue of excessive heat loss in buildings, leading to exorbitant energy bills. However, a promising solution exists in the form of strategically positioned heat flux sensors, which effectively quantify and detect heat loss on building façades, floors, and roofs. By detecting high levels of heat flux on surfaces as a clear indication of inadequate insulation, one can draw attention from energy stakeholders and promote proactive measures.

Surface-mounted heat flux sensors on building façades

By capturing real-world conditions, heat flux sensors provide insights into the actual thermal performance of building components, and facilitate informed decision-making regarding energy efficiency improvements, insulation upgrades, and overall building envelope design. This approach contributes to sustainable practices by optimizing thermal management, reducing heat loss or gain, and mitigating energy consumption and greenhouse gas emissions.

Unveiling Thermal Properties through In-Situ Analysis

The evaluation of thermal resistance and thermal transmittance also plays a pivotal role in assessing the efficacy of insulation materials and systems in minimizing heat flow. Thermal Resistance, commonly denoted as R-value, represents the material's resistance to heat flow. In a solid slab, it is the ratio between the thickness to thermal conductivity and can also be defined as the ratio between the temperature gradient to the resulting/causing heat flux. This parameter is crucial for evaluating the effectiveness of insulation materials and systems in reducing heat flow.

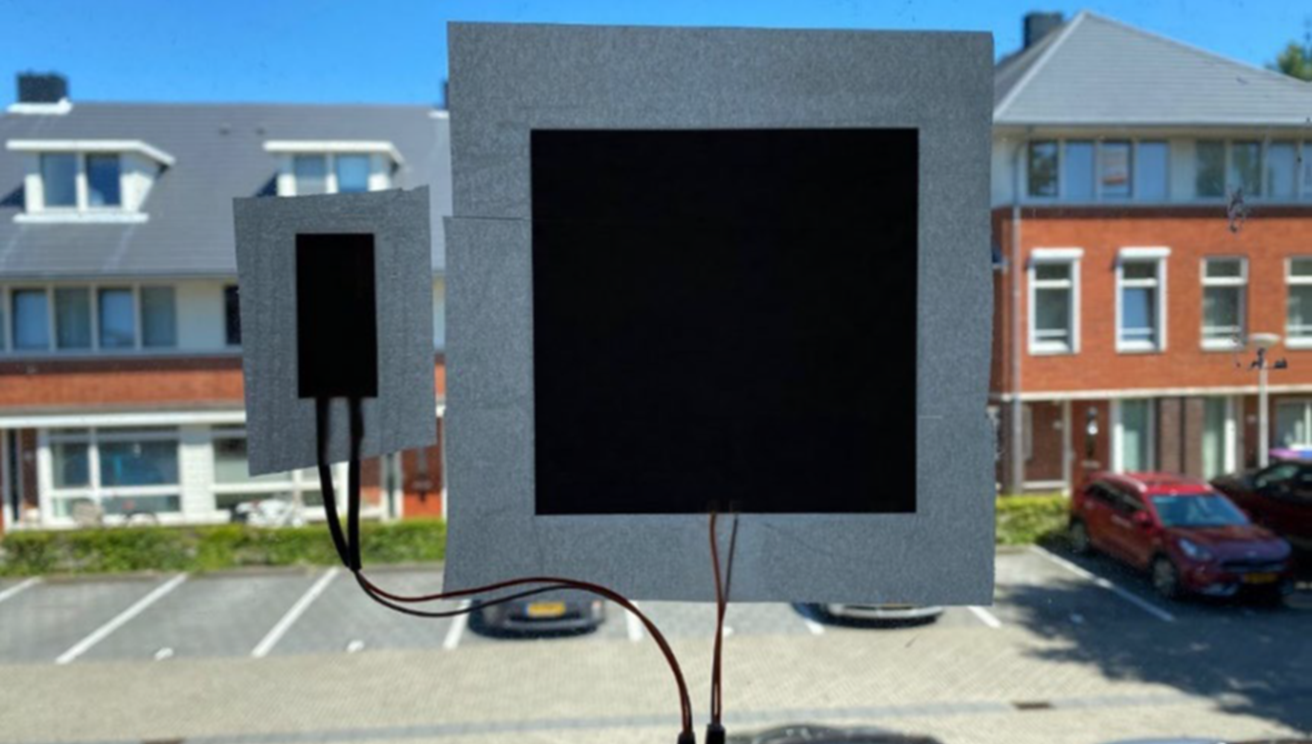

Likewise, Thermal Transmittance, often referred to as U-value, characterizes the overall quality of heat transfer through a structure and combines conduction, convection, and radiation effects. It is based on the reciprocal of thermal resistances and indicates the rate of heat flow caused by a temperature gradient per unit area. Heat flux sensors aid in the precise determination of heat transfer rates, enabling the accurate calculation of thermal transmittance. Using a single heat flux sensor in combination with two temperature sensors, one can determine the thermal resistance R-Value and thermal transmittance U-value of a building component, following the ISO:9869 standard (equivalent to ASTM C1045 and ASTM C1155).

In-situ determination of thermal resistance and thermal transmittance using heat flux sensors offers several advantages. It allows for measurements under real operating conditions, capturing variations in heat transfer due to factors like temperature gradients, airflow, and environmental conditions. This method provides deeper insights into the thermal performance of building components and systems, empowering stakeholders to make informed decisions regarding energy efficiency improvements.

Heat flux sensors used in combination with temperature sensors to determine a building component’s R-value (thermal resistance) and U-value (thermal transmittance)

The adoption of heat flux sensors and the precise analysis of thermal properties have become indispensable tools in the pursuit of energy efficiency and sustainability in the built environment. By harnessing the valuable insights provided by these sensors, we can make informed decisions that optimize thermal management, reduce heat loss or gain, and mitigate energy consumption.

Explore our range of heat flux sensors and thermal analysis instruments, and unlock the full potential of your building's thermal performance, enabling smarter design choices, targeted improvements, and substantial energy savings.